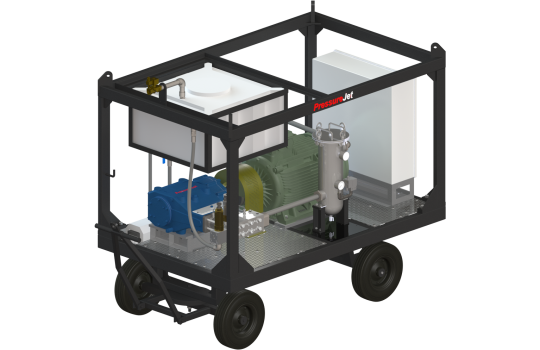

Trusted Hydro Blasting Machine for Surface Preparation and Paint Removal

Experience the power of PressureJet Hydro Blasting Machines, engineered for the toughest surface preparation and paint removal applications across industries. With pressures up to 1400 Bar, 150 HP power and industrial-grade design, PressureJet water blasting machines deliver unmatched performance, efficiency, and reliability. Our advanced hydro blasting solutions are ideal for marine, cement, marble, granite, construction, and industrial maintenance, ensuring thorough cleaning, surface preparation, and coating removal without compromising substrate integrity.

Trusted by professionals worldwide, PressureJet combines precision engineering with superior technical support for maximum uptime and productivity. PressureJet stands out with its commitment to quality and innovation. Each high pressure reciprocating plunger pump development undergoes rigorous 200-hour continuous duty testing to ensure reliability. Our manufacturing process utilizes over 280 quality checking instruments, including advanced 3D Coordinate Measuring Machines (CMM), to guarantee precision.

Applications of PressureJet Hydro Blasting Machines

PressureJet high pressure hydro blasting machines are trusted across industries for a wide range of industrial cleaning applications, including:

- Surface Preparation

- Kiln Cleaning

- Stone texturing

- Paint Removal

- Coating Removal

- Rust Removal

- Stone Washing

Industries Using Hydro Blasting Machine

PressureJet high pressure pump custom systems are widely used by:

- Cement – for efficient cleaning of kilns, resolving cyclone blockages, and removing buildup or ‘snowman’ formations

- Oil & Gas Refineries – External cleaning of heat exchangers and industrial equipment.

- Marine – Paint removal, and surface preparation.

- Marbal and granite – Stone washing, texturing, and surface preparation.

- Engineering Shutdown Maintenance Contractors – External cleaning of tube bundles, heat exchangers, evaporators, condenser tubes, and industrial pipelines.

PressureJet hydro blasting machines deliver efficient scale and coating removal, superior surface preparation, and minimized downtime, while significantly lowering maintenance costs — powered by innovative design, precision engineering, and premium manufacturing quality.

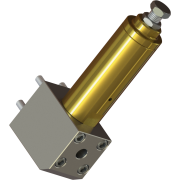

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Provides superior pressure control for extra heavy-duty pump operations

- Rugged T-70 PRV construction ensures durability in extreme conditions.

- Easy installation and minimal service requirements.

- Perfect for hydro jetting, Fin Cleaning, Pipe and tube cleaning, & industrial cleaning industries.

- DG-20 Dump Gun with full SS body engineered for ultra-high pressure operations.

- Suitable for applications up to 1000 bar with assured durability and safety.

- Covered by shockproof semi-housing and ergonomic trigger for operator comfort.

- Perfect for hydro blasting, surface preparation, tank cleaning & industrial jetting.

- Heavy-duty safety suit designed for operators working with ultra-high pressure water jetting

- Made from multi-layer ballistic fabric for cut, puncture and water-jet resistance.

- Ergonomically designed for mobility and comfort during extended operations.

- Includes jacket, trousers, helmet visor and protective boots for full-body safety.

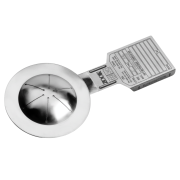

- Rupture disk provides instant pressure relief to protect pumps and operators from overpressure.

- Designed for precise burst pressure ratings to safeguard ultra-high pressure systems.

- Compact design allows easy integration into high-pressure jetting systems.

- Essential safety device for hydro blasting, heat exchanger & industrial cleaning systems.

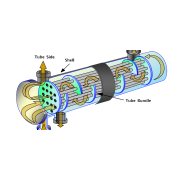

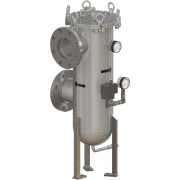

- High-efficiency heat exchanger ensures optimal temperature control in high-pressure descaling systems.

- Constructed with stainless steel and copper-nickel tubes for excellent corrosion and heat resistance.

- Provides stable thermal performance under continuous duty cycles up to 350 BAR.

- Ensures longer pump life and reduced downtime in high-temperature environments.

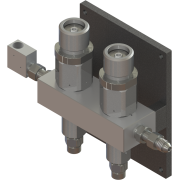

- High-pressure flow divider valve for hydro jetting, blasting, and cleaning after pickling operations.

- Provides equal flow distribution to multiple guns, lances, or rotary nozzles from one pump line.

- Engineered from corrosion-resistant stainless steel for durability in chemical and high-pressure environments.

- Ideal for hydro blasting, chemical cleaning, pickling line cleaning, and industrial maintenance.

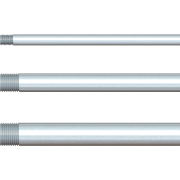

- High-strength rigid lance ensures straight and powerful jet delivery for efficient cleaning.

- Constructed from stainless steel or alloy material ensuring corrosion resistance and long service life.

- Suitable for tube IDs ranging from 16 mm to 60 mm

- Available in custom lengths and pressure ratings up to 1500 BAR.

- High-accuracy pressure gauge for continuous monitoring up to 1500 BAR.

- Built with stainless steel casing and glycerin-filled design to resist vibration and corrosion.

- Provides real-time, precise readings for pump performance and safety assurance.

- Available in bottom or back mount designs with multiple dial sizes for easy integration.

- High-speed rotation for removing thin coatings

- Angled jets allow for broader impact for quicker, more effective cleaning of large surfaces and odd shapes

- Fewer parts and no seals to stock or replace, reducing costs and maintenance downtime

- Short overall tool length and light weight make for easy handling, reducing operator fatigue

- Handles a wide range of pressure ratings from 340-1400 bar

- Simple maintenance for long term use

- New cartridge seal doubles runtime

- Angled jets allow for broader impact for quicker, more effective cleaning of large surfaces and odd shapes

- Flat jet high-pressure nozzle for uniform impact and consistent surface cleaning.

- Rated for pressures up to 700 BAR for hydro jetting and descaling systems.

- Built with stainless steel or tungsten carbide for superior wear and corrosion resistance.

- Available in multiple spray angles and flow capacities for customized cleaning performance.

- High-impact attack tip nozzle for concentrated surface cleaning and coating removal.

- Operates at extreme pressures up to 1400 BAR for hydro blasting and industrial maintenance.

- Available in hardened stainless steel and tungsten carbide for superior wear resistance.

- Ideal for concrete demolition, coating removal, and heavy-duty industrial descaling.