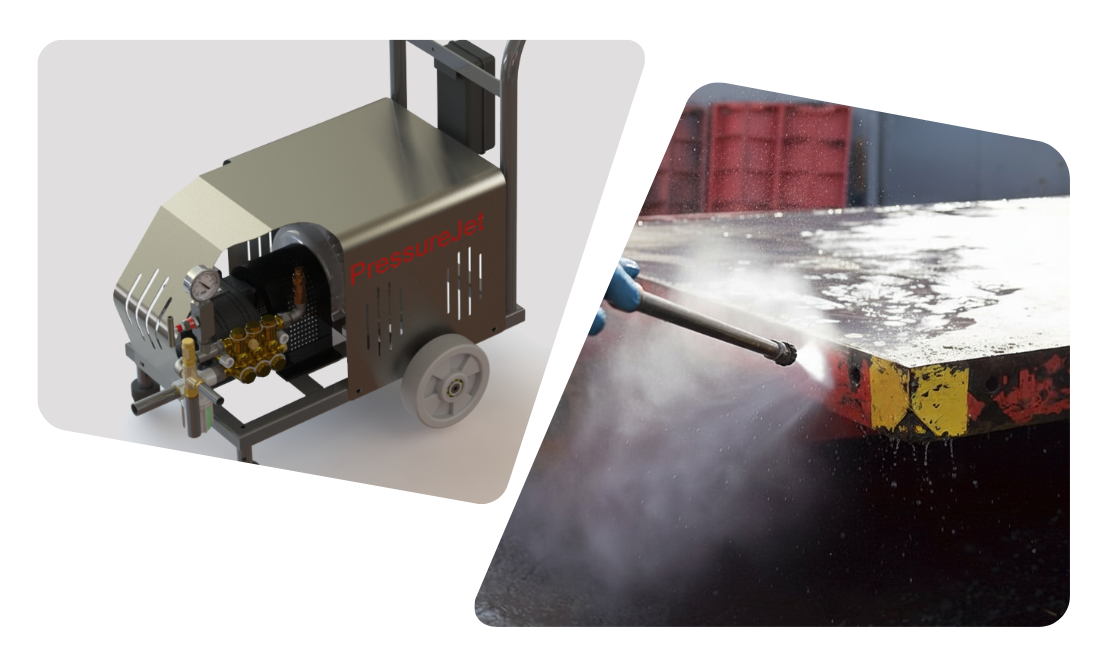

Trusted Brand for Efficient, Eco-Friendly Surface Preparation & Paint Removal thru Water Sand Blasting

PressureJet Water Sand Blasting Machines combine high-pressure water jets with abrasive media to deliver precise, efficient, and environmentally-friendly surface cleaning, paint removal, and rust removal. By blending water with abrasive grit, the wet sandblasting process removes unwanted coatings and corrosion while creating a homogeneous matte finish ideal for recoating and surface preparation.

Widely used in engineering, heavy fabrication, construction, and industrial maintenance, these machines provide superior cleaning without damaging the underlying surface. PressureJet systems are compatible with various abrasive media including sand, baking soda, and plastic pellets, enabling adjustable blasting intensity for specific industrial requirements.

Compact, cost-effective, and easy to operate, PressureJet Water Sand Blasting Machines deliver superior cleaning performance with efficient surface preparation, precise paint and rust removal, and enhanced operational productivity across industries.

Applications of PressureJet Water Sand Blasting Machines

- Engineering & Heavy Fabrication – Surface preparation of metal structures and components.

- Construction – Cleaning steel surfaces, structural beams, and fabricated parts.

- Industrial Maintenance – Rust, scale, and paint removal on machinery and pipelines.

- Recoating Applications – Preparing surfaces for protective coatings or paint.

Enhance your surface preparation quality, reduce operational costs, and achieve cleaner, safer, and more sustainable blasting with PressureJet Water Sand Blasting Machines — engineered for performance, precision, and durability.

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Provides superior pressure control for extra heavy-duty pump operations

- Rugged T-70 PRV construction ensures durability in extreme conditions.

- Easy installation and minimal service requirements.

- Perfect for hydro jetting, Fin Cleaning, Pipe and tube cleaning, & industrial cleaning industries.

- RL-84 Spray Gun designed for medium-to-high pressure cleaning with maximum safety.

- Equipped with Sst seat and ball ensuring precise sealing and long service life.

- Ergonomic handle and trigger design reduce operator fatigue during prolonged spraying.

- Compatible with hoses fitted with G 1/2” connections for easy installation.

- Flat jet high-pressure nozzle for uniform impact and consistent surface cleaning.

- Rated for pressures up to 700 BAR for hydro jetting and descaling systems.

- Built with stainless steel or tungsten carbide for superior wear and corrosion resistance.

- Available in multiple spray angles and flow capacities for customized cleaning performance.

- Flat spray pattern nozzle ideal for surface cleaning and coating removal.

- Operates efficiently at 500 BAR with precise abrasive-water mixing.

- Built from stainless steel and hardened alloy for long service life.

- Built from stainless steel and hardened alloy for long service life.

- Narrow pencil jet for concentrated, high-impact cleaning and descaling.

- Rated for 500 BAR continuous-duty operation.

- Built from stainless steel with precision orifice alignment for stable performance.

- Ideal for metal surface treatment, descaling, and weld cleaning.

- Versatile sand blaster nozzle compatible with plastic and hardened steel inserts.

- Suitable for medium-pressure blasting and surface preparation.

- Delivers uniform mixing of abrasive and water for effective cleaning.

- Ideal for paint removal, oxidation cleaning, and pre-treatment applications.

- High-strength hardened steel nozzle for extended service life.

- Designed for aggressive abrasive blasting and descaling operations.

- Provides stable jet pattern for consistent cleaning results.

- Used for industrial surface preparation, rust removal, and descaling.

- Tungsten carbide nozzle designed for maximum wear resistance and durability.

- Handles pressures up to 500 BAR for heavy-duty blasting applications.

- Provides consistent jet focus and abrasive mixing for superior cleaning.

- Ideal for industrial descaling, paint removal, and surface preparation.

- Compatible with plastic and hardened steel inserts for flexible applications.

- Operates effectively for medium-pressure surface cleaning and preparation.

- Provides uniform abrasive-water mixing for reliable cleaning results.

- Ideal for paint stripping, oxide cleaning, and light industrial descaling.

- High-impact attack tip nozzle for concentrated surface cleaning and coating removal.

- Operates at extreme pressures up to 1400 BAR for hydro blasting and industrial maintenance.

- Available in hardened stainless steel and tungsten carbide for superior wear resistance.

- Ideal for concrete demolition, coating removal, and heavy-duty industrial descaling.