PressureJet UHP Fire Fighting Pump - Power, Precision & Reliability in Advanced Fire Suppression

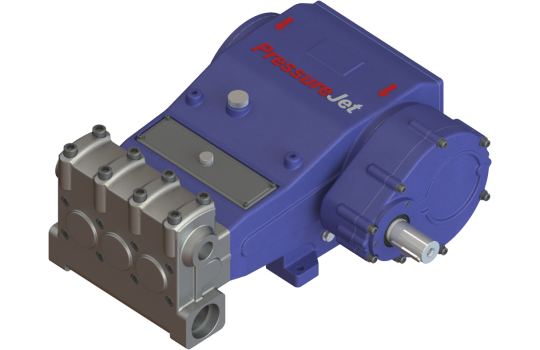

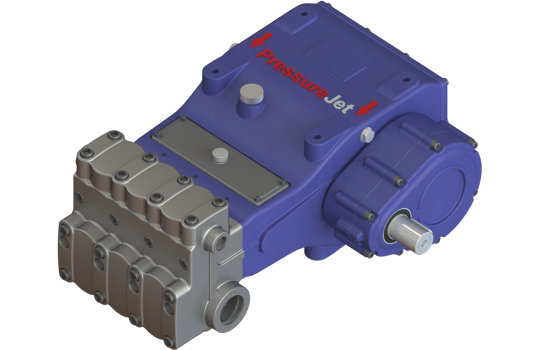

Experience unmatched performance with PressureJet UHP Fire Fighting Pumps, engineered for modern fire-fighting trucks and rapid industrial fire response. Designed to operate between 75 and 200 bar pressure with flow rates from 14 to 485 LPM, these ultra-high pressure triplex plunger pumps deliver precise, high-velocity water jets that maximize fire suppression efficiency while minimizing water damage.

Built with cutting-edge engineering and robust reliability, PressureJet UHP Fire Fighting Pumps ensure dependable performance in demanding fire situations. Trusted by fire departments, industries, and emergency response units, these pumps provide consistent pressure, superior reach, and controlled discharge for safe and effective firefighting.

Each system is precision-engineered for durability, compact design, and ease of integration into mobile and stationary fire-fighting units. Supported by expert technical service, PressureJet guarantees long service life, low maintenance, and uninterrupted readiness for emergency deployment.

Applications of UHP Fire Fighting Pumps

PressureJet UHP Fire Fighting Pumps are widely used for:

- Fire-Fighting Trucks and Rapid Response Vehicles

- Industrial Fire Protection Systems

- Refineries and Petrochemical Plants

- Power Plants and Switchyards

- Marine and Offshore Firefighting Units

- Airports and Hangars

- Municipal Fire Departments

Industries Using UHP Fire Fighting Pumps

PressureJet UHP Fire Fighting Pumps are trusted by:

- Oil & Gas Refineries – for rapid, safe suppression of flammable liquid fires.

- Chemical & Petrochemical Plants – for emergency fire control and asset protection.

- Power Generation Units – for electrical and turbine area fire safety.

- Marine & Offshore Operations – for deck, engine room, and equipment fire suppression.

- Fire Truck OEMs & Contractors – for integration in high-performance fire-fighting vehicles.

PressureJet UHP Fire Fighting Pumps deliver power, precision, and reliability—ensuring rapid response, maximum safety, and minimal water damage in every operation.

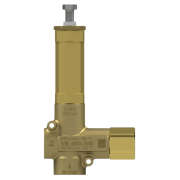

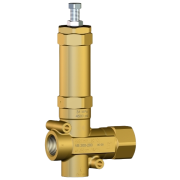

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Light plastic construction

- T Type screen filter (Strainer) used for filter water.

- Glass reinforced polypropylene housing.

- NBR type housing seal used.

- Screen type will be twill weaved SS.

- Covered by shockproof plastic semi-housings

- Entirely built of Sst and body in brass

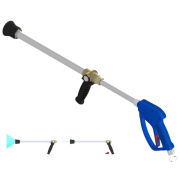

- Ergonomic construction that delivers minimum fatigue during trigger opening and prolonged use.

- Minimum fatigue for trigger opening and use

- RL-84 Spray Gun designed for medium-to-high pressure cleaning with maximum safety.

- Equipped with Sst seat and ball ensuring precise sealing and long service life.

- Ergonomic handle and trigger design reduce operator fatigue during prolonged spraying.

- Compatible with hoses fitted with G 1/2” connections for easy installation.

- RL-34 Foam Gun with integrated eductor for on-the-fly proportioning of foam concentrates.

- Generates high expansion foam for effective coverage and fire suppression.

- Constructed with stainless steel and brass components for durability in harsh environments.

- Compatible with standard foam concentrates and firefighting couplings for swift deployment.

- RL-51 Foam Gun with integrated eductor for on-the-fly proportioning of foam concentrates.

- Designed for rapid intervention in firefighting.

- Constructed with stainless steel and brass components for durability in harsh environments.

- To be used with appropriate foam proportioning systems.

- Special steel spring with superior mechanical features, to maintain calibration settings for longer

- Check valve specifically designed to prevent jammings

- Dynamic seals with O-ring and sliding gasket

- Screw/Locknut adjusment to set maximum pressure level

- Sturdy steel and brass construction

- Hexagonal shaped check valve to avoid jamming.

- Max pressure adjustment by screw and locknut

- Max pressure adjustment by screw and locknut