About Us

Company Profile

Since inception in 1996, PressureJet Systems Private Limited has established a reputation for designing and manufacturing high-quality reliable high-pressure reciprocating plunger pumps and systems. As a NSIC-registered, ISO 9001:2015 certified MSME, we are recognized as

Vision and Mission

We shall be a professionally managed and governed Indian multinational dedicated to developing the most dependable, economical, accessible, and admirable global brand

Promoter's Purpose

The promoter’s purpose is to enable employee growth and development, fostering both personal and professional success while driving organizational growth.

Why PressureJet

Not ONE Indian manufacturer can match the following BASIC USPs of PressureJet!!

Infrastructure

The availability of advanced infrastructure directly impacts the quality of products manufactured. Sufficient and modern facilities enhance the likelihood of delivering superior-quality output, while inadequate

Manufacturing Facility

The manufacture of high-pressure pumps demands exceptionally high-quality components, even at comparatively low volumes. The pump mechanism, similar to an engine, includes a crankshaft, connecting rod, crank-case, and converts rotary motion into reciprocating motion.

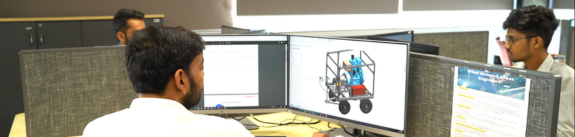

Research and Development

At PressureJet, innovation begins with design. Our in-house Design & Development Department is the creative and technical powerhouse behind every world-class high-pressure pump and system we manufacture. Equipped with cutting-edge tools and driven by an expert engineering team, we consistently deliver designs that are

Quality Approach

PressureJet has invested over INR 10 Million in establishing a state-of-the-art Quality Department. The facility features 7 SCADA-based computerized test benches, capable of simultaneously managing, monitoring, and controlling the testing of pumps across the power range of: 30 HP to 330 HP.

Inventory Management

At PressureJet, we understand that every minute of downtime impacts operations, which is why our approach to service and spares delivery is as precise and reliable as our pumps.

Procurement Strategy

At PressureJet, procurement is not merely a transactional function — it is a strategic cornerstone of our world-class manufacturing ecosystem. Our Purchase Department plays a pivotal role in ensuring that every component sourced contributes to consistent quality, timely delivery, and competitive pricing — the three pillars of PressureJet’s promise of excellence.

Information Technology

PressureJet has its own data center that is equipped with the latest IBM servers, licensed software and other essentials. We have also installed a Linux server for the Oracle e-Business Suite that we employ in managing various day-to-day aspects of our business.

Certification and Awards

ISO 9001:2015 Certificate, HAWK Champion Distributor Certificates