High Pressure Water Jet Cleaning

High pressure water jet cleaning, commonly known as hydro blasting, is a widespread abrasive water discharge operation. As such, it is very successful because of its powerful blasting effect. In most cases, because of its efficiency, hydroblasting will require only one operator for a given application.

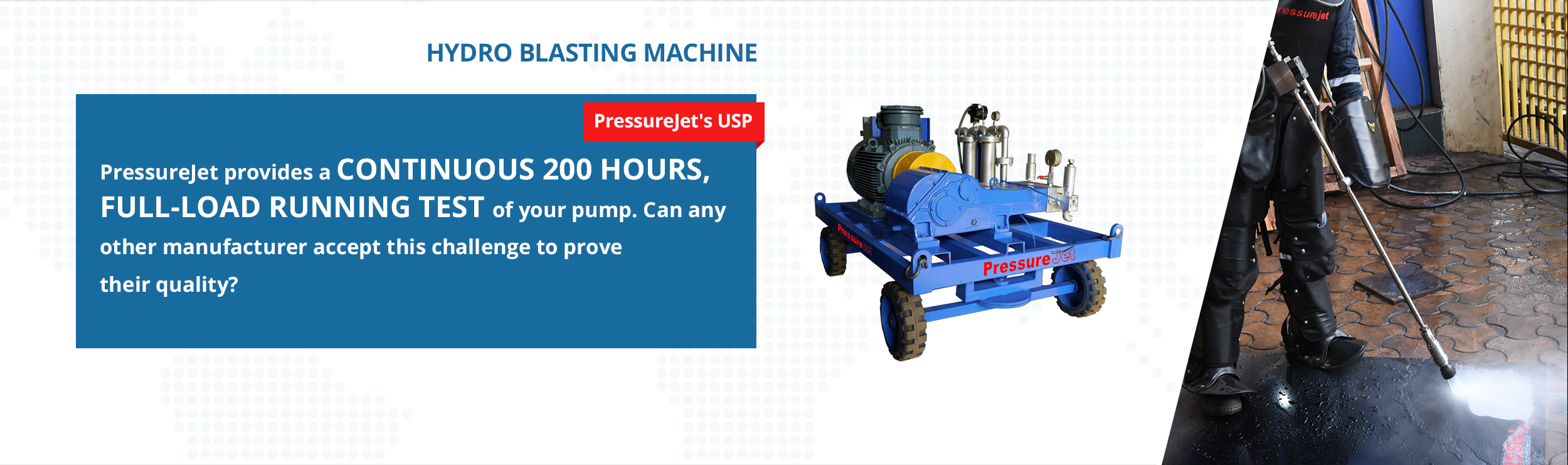

Pressure and Flow both play key roles in efficient high pressure water jet cleaning, and applications respond differently to each variable. Typically, hardened deposits respond better to higher pressures, and softer materials are best removed with higher flows. Each application is unique, though, and we can help you determine which combination of pressure and flow will work best for you. Aqua blasting is the method, by which a high pressure stream of water (450 bar or more) is used to remove old paint, rust, rubber, chemicals, or other heavy build up without causing damage to the surface below it. This method is perfect for internal and external surfaces because the spray gun operator is able to access those “hard to reach” areas (such as pipelines). Also, because of its strong water spray, the user can keep a safe distance from the surface being cleaned. One of the major differences between high pressure water jet cleaning and other cleaning abrasives (such as silica sand, coal or smelter slag, metallic, synthetic, organic nut shells or fruit kernels) is the ability to contain, capture, filter and reuse the water. This eliminates waste water and contaminants after the cleaning. Extremely high pressure water jet cleaning (2800 bar or greater) are used for concrete cutting. If your requirement is high pressure, high water volume and high temperature output machine, then your answer is in heavy duty hydroblaster pressure washer. Due to the high removal and cleaning power, these hydrojetting machines pay for themselves after a very short period of time. High pressure water jet cleaning are ideal for specialized service providers, construction companies, renovators and for industry. High pressure water jet cleaning pumps consists of bare pump, electric motor and starter, pressure regulating valve, safety valve and pressure gauge. Other accessories include suction hose, delivery hose, foot valve/gun, nozzles, rigid lance and flexible lance.

Advantages: Reduction of plant downtime, labour saving, plant protection, water conservation, no need of chemicals and non hazardous.

Applications: For cleaning of rotary kiln, agitators, riser ducts, turbines, cooling towers, pump impellers filters and hoppers, mixers, ship hulls, conveyers, etc.

APPLICATIONS FOR THESE UNITS INCLUDE

- Hydro demolition

- Investment casting cleaning

- Oxidation removal at 36,000 psi

- Chloride removal from concrete

- Asbestos removal

- Corrosion removal from pilings

- Historic cobblestone restoration

- Pool refurbishing

- Marine surface prep

- Prep for highway overlay

- Paint removal from ships

- Water jet cutting

- Concrete surface preparation

- Surface preparation

- Tank cleaning

- Heat exchanger tube cleaning & pipe cleaning

- Descaling

- Vessel cleaning

- Deburring

- Oil field cleaning applications sewer jetting

- Ship hull cleaning

IMPORTANT ACCESSORIES FOR HIGH PRESSURE WATER JET CLEANING

- Trigger operated gun

- Dump gun

- Unloader cum pressure regulator valve with by-pass system

- Straight jet nozzle

- Fan jet wash nozzle

- Rotating nozzle – barracuda

- High pressure hose

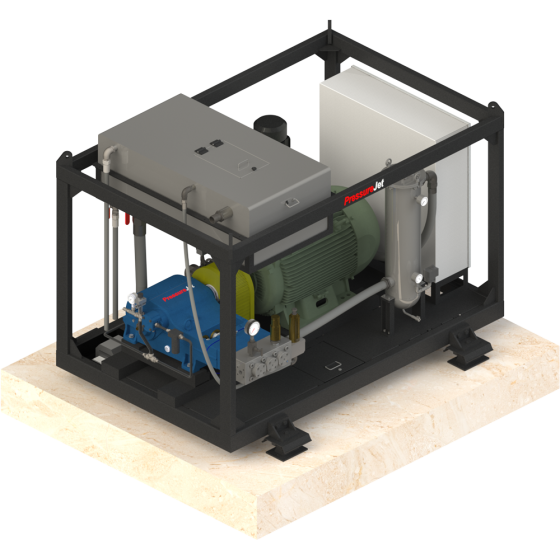

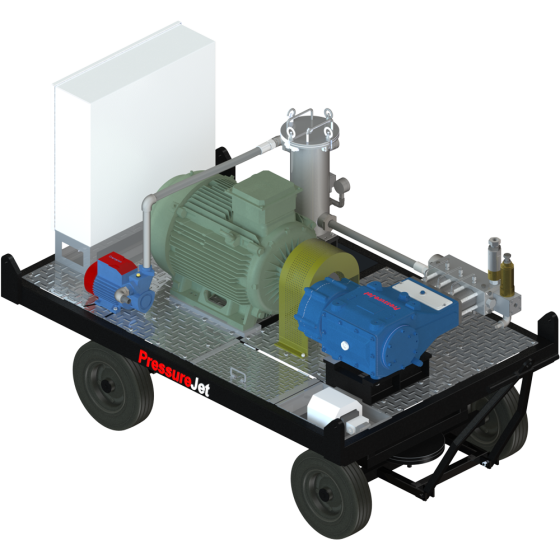

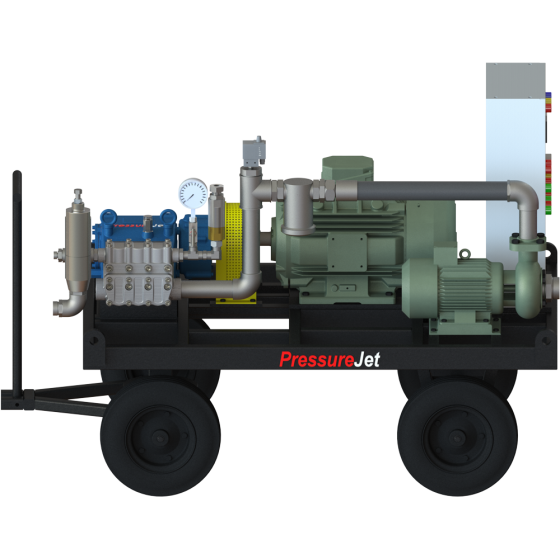

- 4 wheel heavy trolley mounted unit

- Can be driven with electric motor / engine

- Glycerine filled pressure gauge

- Electric control panel with auto cut-off system

- Pipe drain cleaning accessories

- Rotopower turbo nozzle

- Variable nozzle head with fan/pencil jet spray

- Flexible lance

- Hose reel

- Sewer jetting nozzle

- Tube - pipe cleaning nozzle