Heat Exchanger Tube Cleaning Systems

You’re at the right place for advanced tube cleaning solutions. PressureJet provides high-pressure hydrojetting systems for heat exchanger, condenser, and evaporator tube cleaning, as well as various industrial pipe cleaning applications.

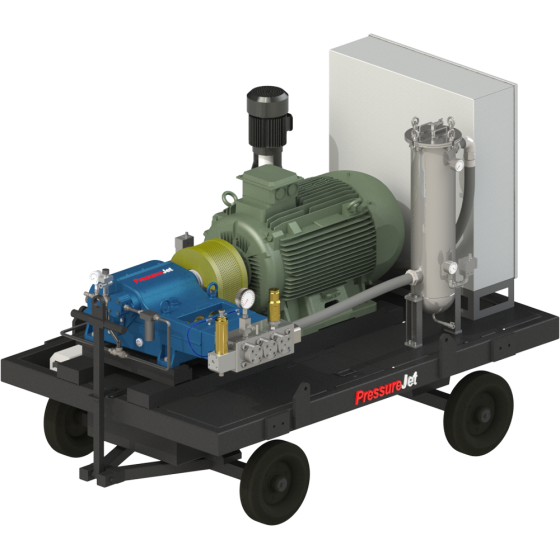

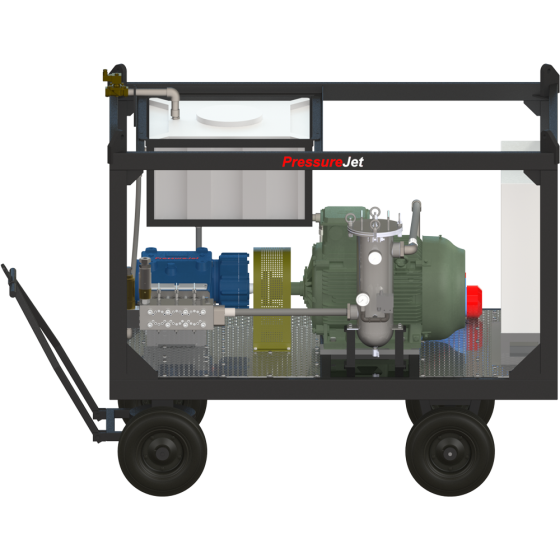

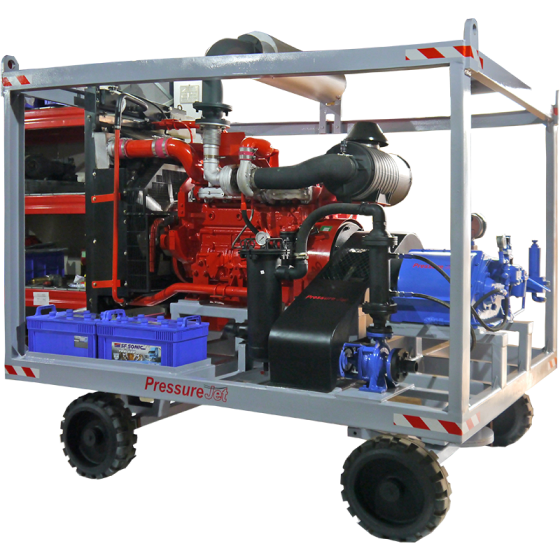

Our high-pressure reciprocating plunger pumps offer a pressure range from 100 bar up to 2800 bar and flow rates up to 700 LPM, making them ideal for even the most challenging cleaning tasks.

Why Choose High-Pressure Hydro jetting Over Conventional Methods?

High-pressure waterjet tube cleaning offers several advantages compared to chemical cleaning, brushes, or mechanical methods:

-

Safe for all tube materials – From brass to titanium, without causing damage.

-

Prevents corrosion & extends tube life – Removes corrosive deposits and tube pits.

-

Universal application – Cleans any length or diameter of straight or U-tube heat exchangers.

-

Improves operating efficiency – Removes fine silt and organic debris that mechanical cleaning often misses, preventing rapid refouling.

-

Removes all foreign scale deposits

-

Environmentally friendly – No chemical discharge or hazardous waste.

-

Custom-designed nozzles – Ensure 360° inner diameter cleaning without streaking.

-

Multiple lance systems – Up to 8 (or more) operators for fast cleaning of large condensers.

-

Radiological waste minimization – Positive shut-off pressure control systems.

-

Cost-effective – Restores baseline performance quickly and reduces refouling frequency.

Applications

High-pressure tube and pipe cleaning is widely used in industries such as:

-

Textiles

-

Pharmaceuticals

-

Steel & Metallurgy

-

Chemical Processing

-

Refineries

-

Power Plants

-

And many more

PressureJet has supplied tube & pipe cleaning systems across India and internationally to countries including South Africa, Malaysia, Philippines, Thailand, Korea, Iran, Saudi Arabia, Brazil, Mexico, Israel, Indonesia, and more.

Pump Options

-

Diesel engine-driven pumps available for remote or heavy-duty applications.

-

Modern high-pressure waterjet systems leave a smooth, residue-free surface, eliminating the need for chemical disposal and reducing cleanup costs.

Key Accessories for Tube & Pipe Cleaning

PressureJet offers a wide range of specialized tube & pipe cleaning accessories:

-

Forward, backward, radial, and combination firing nozzles

-

Rotating tube cleaning nozzles

-

High-pressure flexible lances

-

High-pressure waterjet rubber hoses

-

Foot-operated valves

-

Pneumatically controlled flexible lance systems

-

Automatic lancing machines with rigid lances

-

Telescopic positioning devices

-

Centralisers and lancing rails

-

Single, dual, and triple lancing systems

-

Hose catcher anti-withdrawal devices

-

Line mole backout preventers

PressureJet High-Pressure Tube Cleaning Systems – Efficient, safe, and environmentally friendly solutions for maximum heat exchanger, condenser, and evaporator performance.