High Pressure Washing

PressureJet is leading Manufacturer of India providing High Pressure Washer, High Pressure Washer Pump, High Pressure Washing System, High Pressure Water Jet Pump in India, China, UK, USA, Philippines, Russia, Bangladesh, Brazil, South Africa and all over the world.

Commercial & industrial pumps is a high pressure reciprocating plunger pump that uses high pressure water jet to remove mold, grime, dust, mud and dirt from surfaces and objects such as buildings, vehicles and concrete road surfaces. A pressure washer is also known as power pressure washer.

Commercial & industrial pumps direct a high-pressure stream or jet of water against a surface to clean, descale, degrease or prepare a surface. Pressure washer cleaners may use either cold water or hot water and steam to perform their function, and the water is often mixed with various cleansers, detergents or solvents. They are used for surface cleaning, or for the demolition of products made of metal, wood, concrete, stone, plastic, glass or other building materials.

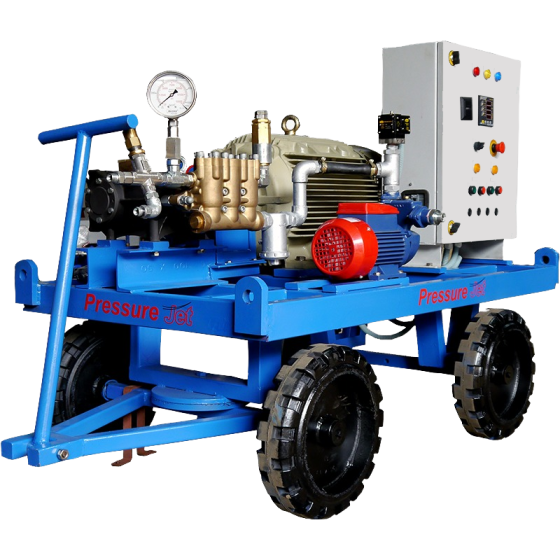

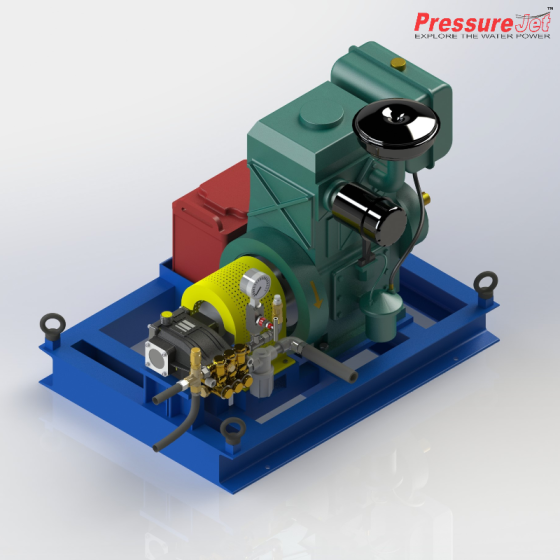

High pressure washers are available as complete machines or systems, or they can be purchased in component form and built from the ground up, or to replace worn out parts. water blast wheel, and water storage tank.

The gun or lance directs the stream fluid through a nozzle and at the appropriate region of the work piece. Some pressure washers have wear resistant nozzles and optional abrasive injectors to provide wet sandblasting capability.

Several different types of nozzles are available, each useful for a particular application. Some nozzles cause the water jet to be ejected in a triangular plane, while others emit a pencil-thin jet of water, which spirals around rapidly. Most nozzles attach directly to the trigger gun.

Some Pressure Power washer, in combination with a particular nozzle, allow detergent to be introduced into the water stream, assisting in the cleaning process. Two types of chemical injectors are available: a low-pressure injector and a high pressure injector.

The pumping unit is the pressure generator used to force out the carrier fluid at high velocity. Plunger-type pressure washer pumps are commonly used to generate high pressure water for water jet cleaning and wet or water abrasive blasting for non-abrasive pressure washing or rinsing. Crankshaft driven plunger pumps are commonly used for pressure generation. Crankshaft driven plunger pumps may be more efficient in electrical energy costs compared to intensifiers. Crankshaft driven plunger pumps also provide a virtually ripple free pressure source in comparison to intensifiers. Dust collection or filtration systems remove fine particle sizes of abrasive, swarf, grease or other blasting waste (removed scale or stock in the form of dust or fine swarf) that would otherwise contaminate the environment.

Water tanks or hoppers are used by water pressure washers for the storage of dry abrasive grains, blasting media or abrasive-water slurry mixtures.

THE MOST BASIC HIGH PRESSURE WASHER CONSISTS OF:

- A Motor / Engine

- High Pressure Hose (Available in Different Sizes)

- Trigger Operated Gun

- Unloader Valve

- Lances (Available in Different Sizes)

- Nozzles

- Pressure Relief Valve

- Pressure Gauge