High Pressure Cleaning Systems

High-pressure cleaning systems are industrial-grade solutions featuring reciprocating plunger pumps that generate powerful water jets to remove mold, grime, dust, mud, and dirt from surfaces such as buildings, vehicles, industrial equipment, and concrete roads. Also referred to as power pressure washers, these systems are designed for heavy-duty industrial, commercial, and specialized cleaning applications.

How High-Pressure Cleaning Systems Work

Electric high-pressure cleaning systems deliver a focused high-pressure water stream to clean, descale, degrease, or prepare surfaces. They can operate with cold water, hot water, or steam and may be combined with detergents or solvents for enhanced cleaning. Common applications include:

-

Surface cleaning and maintenance

-

Degreasing and rinsing of equipment

-

Removal of deposits or scale from metal, wood, concrete, stone, plastic, or glass

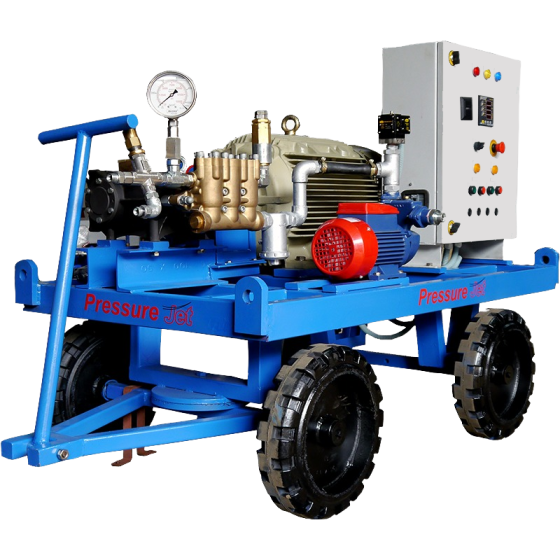

System Components

High-pressure cleaning systems are available as complete machines or modular setups, and can also be built from components to replace worn-out parts. Core components include:

-

Motor / Engine

-

High-pressure hose

-

Trigger-operated gun

-

Lances

-

Nozzles

-

Unloader valve

-

Pressure relief valve

-

Pressure gauge

-

Optional water blast wheel and storage tank

The gun or lance directs water precisely onto the target surface. Some systems feature wear-resistant nozzles and optional abrasive injectors for wet sandblasting, while hot water cleaning options are available for more demanding applications.

Nozzle Options & Chemical Injection

-

Nozzle types for specific tasks:

-

Triangular-plane sprays

-

Pencil-thin spiraling jets

-

Direct attachment to trigger gun

-

-

Chemical injection options for enhanced cleaning:

-

Low-pressure injectors

-

High-pressure injectors

-

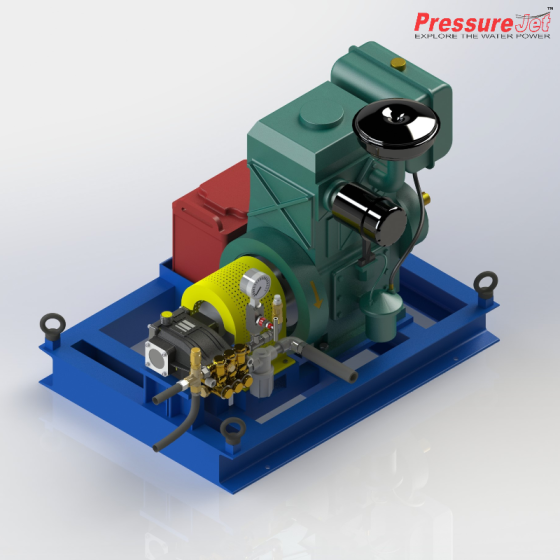

Pump Technology

-

Plunger-type pumps generate high-pressure water for cleaning, wet abrasive blasting, or rinsing

-

Crankshaft-driven plunger pumps offer:

-

Improved energy efficiency compared to intensifiers

-

Ripple-free pressure for consistent performance

-

-

Dust collection and filtration systems remove fine particles, swarf, grease, and other debris, maintaining a clean and safe environment

Water tanks or hoppers can store dry abrasives, blasting media, or abrasive-water slurry mixtures for wet abrasive applications.

How to Select High-Pressure Cleaning Systems

Choose a system based on power source and application requirements:

-

Electric high-pressure cleaning systems

-

Gas-powered high-pressure cleaning systems

-

Diesel-powered high-pressure cleaning systems

-

Hydraulic high-pressure cleaning systems

-

Honda engine-driven cleaning systems

-

Trailer-mounted high-pressure cleaning systems

PressureJet High-Pressure Cleaning Systems – Efficient, reliable, and powerful solutions for industrial and commercial cleaning.