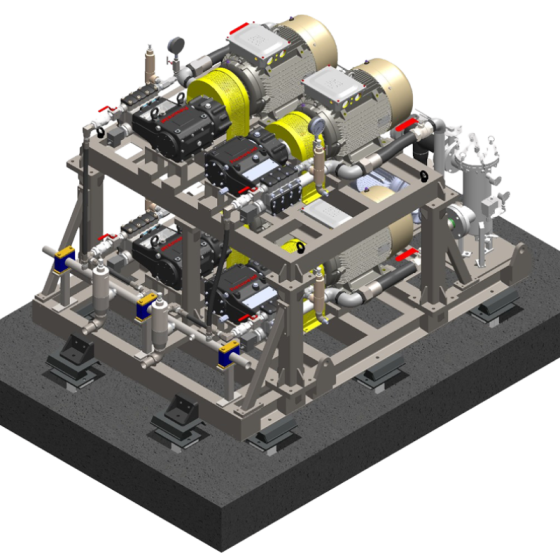

Combine Hydro Test System

In hydro test applications where high volume and high pressure are required in a short time, and testing is frequent, a Combine Hydro Test System offers a reliable, fast, and cost-effective solution.

System Configuration

A Combine Hydro Test System typically consists of two or more pumps:

-

High-flow, low-pressure filling pump

-

Medium-flow, medium-pressure pump

-

Low-flow, very high-pressure pump (optional in some cases)

This modular arrangement ensures that water is delivered efficiently, with the right flow and pressure at every stage of the test.

Why Use a Combine Hydro Test System?

Example Scenario:

-

Tank volume: 10,000 liters

-

Test pressure: 500 bar

-

Available time: 10 minutes

Challenge:

A single pump capable of delivering 1,100 LPM at 580 bar would require 1,700 HP, which is neither feasible nor cost-effective.

Solution with a Combine Hydro Test System:

-

High-flow, low-pressure filling stage:

-

Use a submersible, vertical turbine, or high-flow low-head pump (1,400 LPM at 6 bar, ~40 HP) to fill the tank in ~7 minutes.

-

-

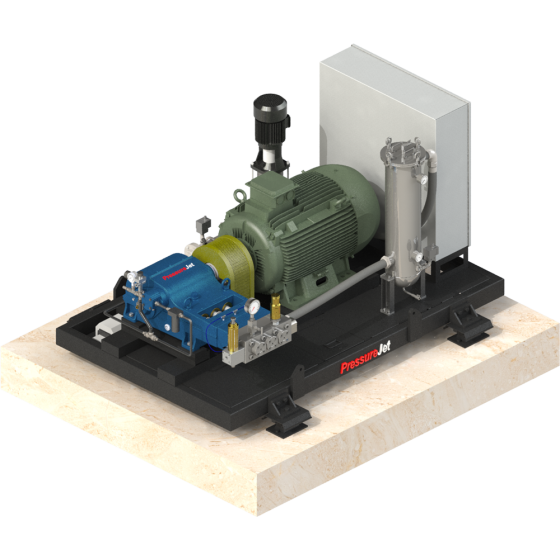

Medium-flow, medium-pressure stage:

-

A medium-flow pump (500 LPM at 60 bar, ~75 HP) feeds water and starts pressurizing the tank.

-

The high-flow filling pump continues to feed water simultaneously for ~5 minutes 20 seconds.

-

-

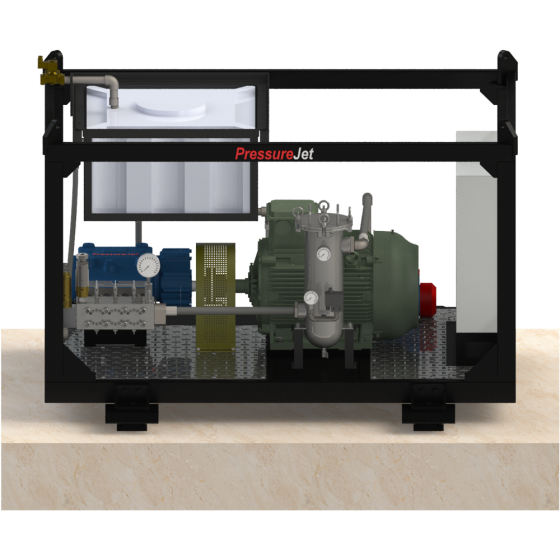

Low-flow, high-pressure stage:

-

After the tank reaches ~60 bar, the high-pressure, low-volume pump (30 LPM at 500 bar, ~40 HP) is activated.

-

This pump pressurizes the remaining volume (~60 liters) to 500 bar within 2 minutes.

-

Result:

-

Total test time: ~8 minutes 20 seconds

-

Maximum connected load: <120>

-

Total cost: Much lower than a single 210 HP, high-pressure pump

-

Mobility: Easy transport and setup of multiple skid-mounted pumps

Key Advantages of Combine Hydro Test System

-

Lower connected load – Efficient use of power at every stage

-

Cost-effective – Total pump cost is significantly lower than a single high-power unit

-

Fast and reliable – Achieves high-pressure testing within short time frames

-

Flexible and modular – Easy to transport and deploy multiple skid-mounted pumps

Combine Hydro Test System – Optimized flow, precise pressure, and maximum efficiency for high-volume hydro testing.