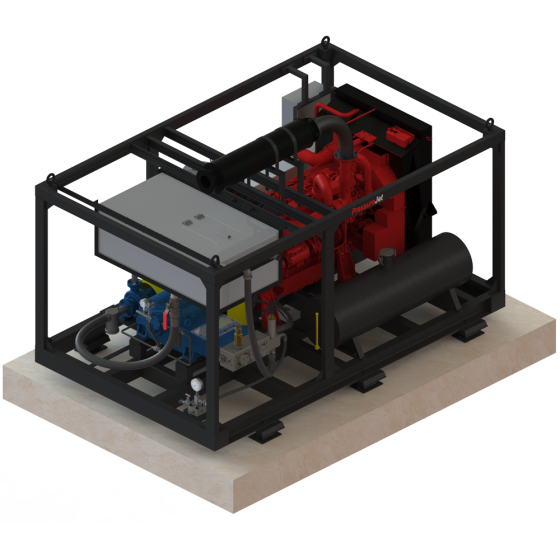

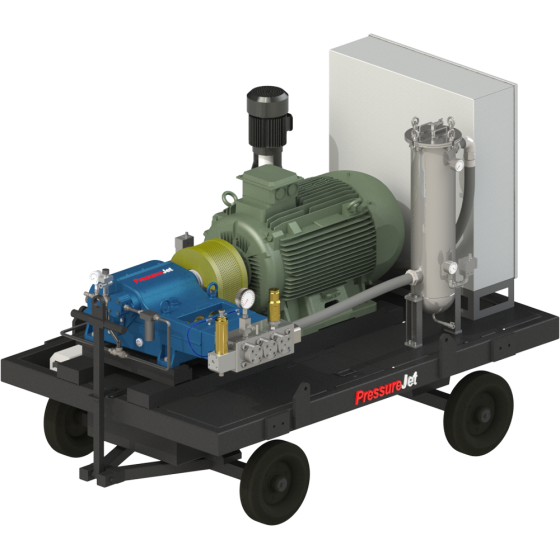

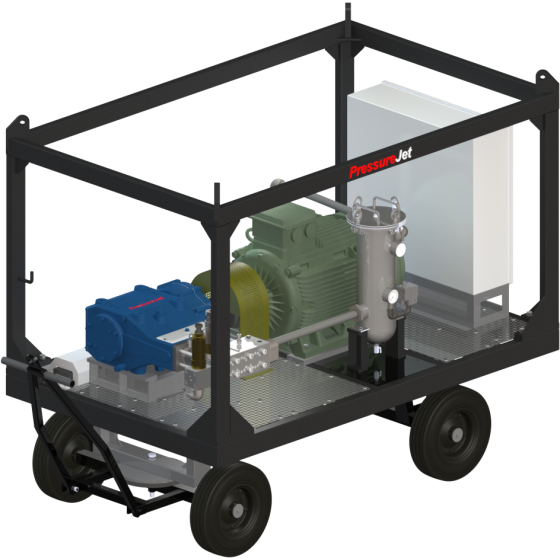

High Pressure Hydro Blast Machine

High-pressure hydro blasting, also known as water jetting or water blasting, utilizes the power of high-pressure water jets for effective surface cleaning and preparation. Unlike abrasive cleaning methods, hydro blasting depends entirely on the impact energy of water to remove rust, coatings, dirt, grease, and chemical deposits from various surfaces.

Since no abrasives are used, challenges related to dust pollution and disposal of spent media are completely eliminated, making it an eco-friendly and efficient cleaning process.

Surface Condition After Hydro Blasting

Flash Rust Formation

During large-scale operations using High Pressure Hydro Blast Machines, a phenomenon called flash rust may appear on freshly cleaned steel before coating or painting. The extent of flash rust formation depends on humidity, temperature, and surface exposure time.

Degrees of Flash Rust:

-

Light Flash Rust: Slight tan-brown discoloration appears; brushing leaves no mark.

-

Medium Flash Rust: Thin, tan-brown layer forms uniformly or in patches; light brushing may leave marks.

-

Heavy Flash Rust: Dense, dark brown rust layer covers the surface completely; easily marks on contact.

Temperature Effect

The use of High Pressure Hydro Blast Machines raises the surface temperature of the substrate, which accelerates drying and helps reduce flash rust formation, ensuring a clean and ready-to-coat surface in less time.

Removal of Foreign Elements

High-pressure water efficiently eliminates oil, grease, and salt deposits while cleaning.

Any discoloration remaining after blasting—typically grey, brown, or black—is mainly composed of ferric oxide, an inert and tightly adherent compound that does not affect coating adhesion or surface quality.

Surface Profile

High Pressure Hydro Blast Machines do not inherently create a surface profile. Any texture revealed after cleaning results from previous surface preparation or corrosion. On weakened or corroded metal, minimal erosion may occur but within safe and acceptable limits.

Advantages of High Pressure Hydro Blast Machines

-

Eco-friendly – No chemicals or abrasives required

-

Highly efficient – Removes oil, grease, salts, and deposits effectively

-

Minimizes flash rust – Faster drying due to temperature rise

-

Safe for sensitive surfaces – Gentle yet powerful cleaning

-

Delivers a residue-free finish – Ready for coating or inspection