Experience Industrial Cleaning Power — Choose PressureJet!

PressureJet has been at the forefront of high-pressure water jet cleaning technology for over three decades. Our expertise lies in delivering world-class cleaning solutions through:

Upgrade to PressureJet Industrial High Pressure Cleaners and achieve fast, efficient, and cost-effective cleaning.

- Proven Partnership with Hawk, Italy – As India’s largest importer and champion distributor since 2012.

- Ex-Stock Availability – 700+ Hawk pumps and spares worth ?6 crore ready for immediate dispatch.

- Technical Superiority – Pumps designed to perform between 2,000 and 7,000 PSI (140–500 Bar) for a wide range of industrial cleaning applications.

- Unmatched Service Support – Through ex-stock spares and detailed maintenance videos ensuring minimal downtime.

- Commitment to Customer Success – Delivering reliable performance, faster cleaning cycles, and reduced operational costs.

Applications of PressureJet Industrial High Pressure Cleaners

PressureJet High Pressure Cleaners are engineered to perform across multiple industrial cleaning and preparation tasks, such as:

- Surface Cleaning – Removes oil, grease, and contaminants from floors, walls, and machinery.

- Paint & Coating Removal – Prepares metal and concrete surfaces for repainting or recoating.

- Post-Pickling Cleaning – Effectively cleans stainless steel surfaces after chemical treatment.

- Dust & Dirt Removal – Eliminates dry or sticky industrial dust from structures and equipment.

- Equipment & Vehicle Washing – Maintains cleanliness of heavy machinery, transport vehicles, and tools.

- Floor Cleaning – Ideal for workshop, plant, and warehouse floor cleaning.

- Maintenance & Shutdown Cleaning – Supports engineering contractors for cleaning during plant shutdowns.

- Pre-Surface Treatment Preparation – Ensures perfect surface finish before painting, coating, or plating.

Industries Using Industrial High Pressure Cleaners

PressureJet Industrial High Pressure Cleaners are trusted by diverse industries for their ability to deliver fast, deep, and economical cleaning performance. Designed for durability and reliability, these cleaners are ideal for a wide range of applications in:

- Steel Plants & Metal Finishing Units – For cleaning after pickling, degreasing, and descaling metal surfaces.

- Pharmaceutical & API Manufacturing Units – For cleaning reactors, storage tanks, centrifuges, and process pipelines to maintain hygiene and prevent cross-contamination between production batches.

- Automotive & Engineering Industries – For component cleaning, maintenance bay washing, and pre-paint surface preparation.

- Cement Plants – For cleaning floors, silos, and removing stubborn dust and deposits.

- Chemical & Process Industries – For cleaning tanks, reactors, and pipelines after production or maintenance.

- Food & Beverage Processing Units – For hygienic cleaning of equipment, conveyors, and production areas.

- Textile & Dyeing Units – For cleaning dye tanks, floors, and process machinery.

- Construction & Infrastructure – For site cleanup, equipment washing, and surface preparation.

- Power Plants & Utilities – For cleaning turbine housings, heat exchangers, and cooling systems.

- Marine Industry – For deck cleaning, hull maintenance, paint removal, rust removal, and surface preparation on ships, boats, and offshore platforms.

- RL-84 Spray Gun designed for medium-to-high pressure cleaning with maximum safety.

- Equipped with Sst seat and ball ensuring precise sealing and long service life.

- Ergonomic handle and trigger design reduce operator fatigue during prolonged spraying.

- Compatible with hoses fitted with G 1/2” connections for easy installation.

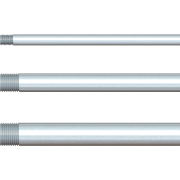

- High-strength rigid lance ensures straight and powerful jet delivery for efficient cleaning.

- Constructed from stainless steel or alloy material ensuring corrosion resistance and long service life.

- Suitable for tube IDs ranging from 16 mm to 60 mm

- Available in custom lengths and pressure ratings up to 1500 BAR.

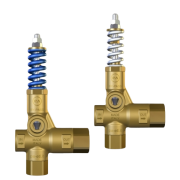

- Designed for pressures up to 280 BAR with flow capacity up to 80 LPM.

- Optimized internal passages that guarantee reduced pressure loss.

- O-rings of the fittings positioned upstream to the thread : no risk of fittings ejected in case of overpressure.

- Version with knob fitted with locknut for minimum working pressure adjustment.

- High-pressure discharge hose rated up to 1400 BAR

- Constructed with multi-wire steel braid reinforcement for superior strength and flexibility.

- Outer cover made of oil, abrasion, and ozone-resistant synthetic rubber for long life.

- Compatible with PressureJet fittings, nozzles, and accessories for safe, leak-free operation.

- Rated for 600 BAR for heavy-duty cleaning.

- Built entirely from stainless steel for extreme corrosion and wear resistance.

- Provides 360° uniform rotation for high-impact cleaning results.

- Perfect for hydro jetting and tube bundle cleaning.