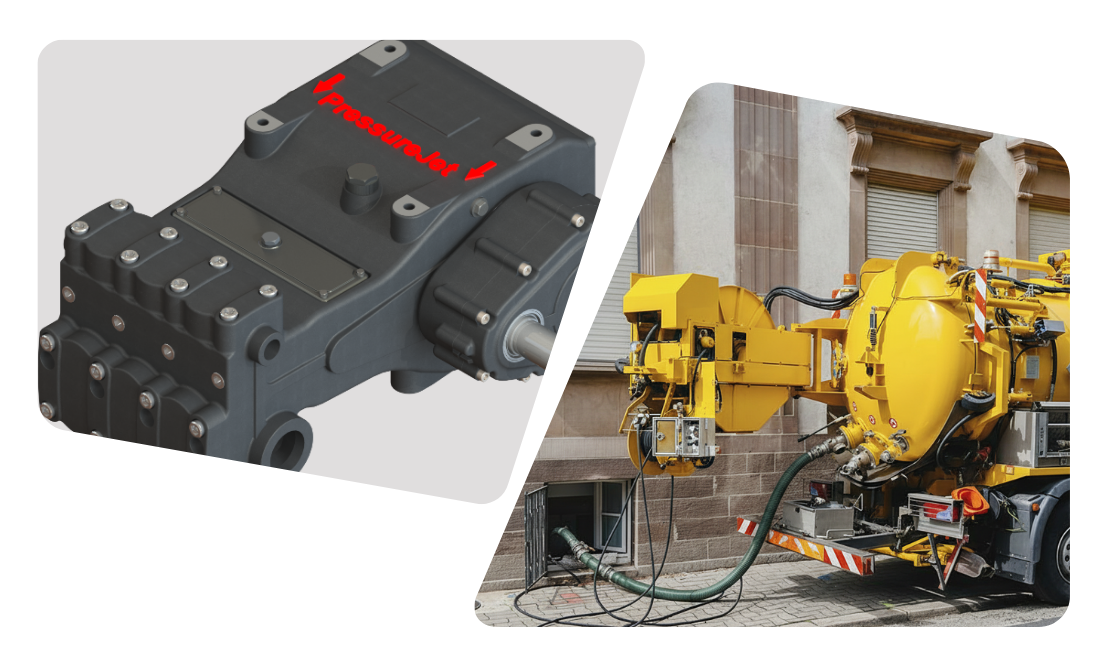

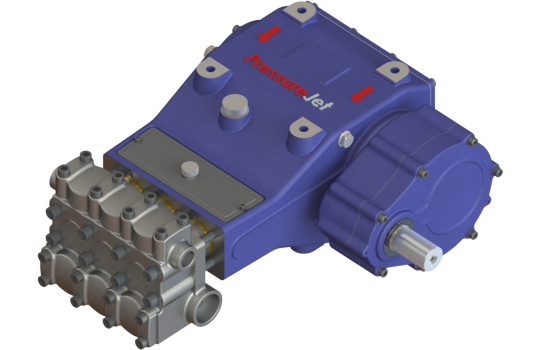

Sewer Jetting Pump is an essential in regular period to avoid blocking of sewer and pipes. If scale/residual is not removed regularly it may narrow cross section of Sewer pipes and lead complete failure of sewer lines. High Pressure Sewer Jetting Pump is environment friendly method compare to chemical cleaning method.

PressureJet has been manufacturing high quality Sewer Jetting Pumps in India for last 25+ years. We are the first choice of Sewer Cleaning / Sewer Jetting Contractor and Sewer Cleaning Vehicle manufacturer worldwide. We have complete solution of sewer cleaning with high performance cleaning nozzles which removes complete residue from the pipes. These kinds of systems are successfully running in different municipal corporations.

Working Pressure: 125-200 Bar

Max. Discharge Flow Rate: 485 LPM

- Ensures maximum safety by releasing excess pressure automatically.

- Compact S-20 Safety Valve built for reliability and long life.

- Quick response mechanism for over-pressure protection.

- Widely used in hydro jetting, descaling, tube cleaning & industrial cleaning.

- Light plastic construction

- T Type screen filter (Strainer) used for filter water.

- Glass reinforced polypropylene housing.

- NBR type housing seal used.

- Screen type will be twill weaved SS.

- Delivers precise pressure regulation for large high-flow pump systems

- Heavy-duty T-60 PRV designed for maximum industrial performance.

- Simple to install with low maintenance requirements

- Perfect for hydro test, descaling, tube cleaning, sewer jetting & industrial cleaning applications.

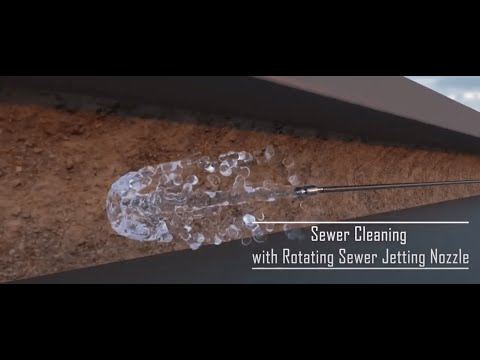

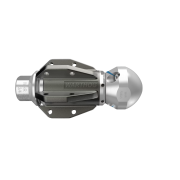

- Rotating drain cleaning head cutter engineered for powerful jetting and mechanical cutting action.

- Handles pressures up to 300 BAR for efficient removal of obstructions and deposits.

- Made from high-grade stainless steel for corrosion resistance and long life.

- Ideal for industrial drain, pipe, and sewer cleaning applications.

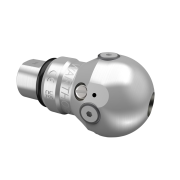

- Rotating spherical head nozzle for uniform cleaning inside pipelines and drains.

- Operates at pressures up to 500 BAR with smooth rotation and balanced jetting.

- Built from stainless steel for superior strength and corrosion resistance.

- Perfect for industrial drain, pipe, and sewer maintenance.

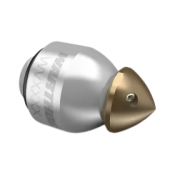

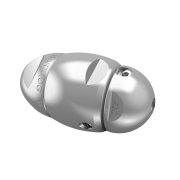

- Jetted for an equal balance of pulling/flushing and cleaning/cutting

- Head can be replaced when worn to keep the tool operating at peak performance

- Without seals or bearings to service, tool is low maintenance with easy-to-change head replacements

- Perfect for 2-4 in. / 50-100 mm industrial drain, pipe, and sewer cleaning.

- Ball design reduces hang-ups

- Maneuverable in multiple elbows

- Repairable and rebuildable, field serviceable

- Perfect for 3-6 in. / 75-150 mm industrial drain, pipe, and sewer cleaning.

- Equipped with a whip hose to increase maneuverability

- Compact and highly maneuverable

- Tackles a mix of routine and challenging jobs

- Perfect for 4-8 in. / 100-200 mm industrial drain, pipe, and sewer cleaning.

- Adjustable jet sizes can focus the flow on pulling or towards descaling and cutting

- Viscous fluid ports simplify field maintenance

- Unique shape and design to easily maneuver long radius elbows

- Perfect for 4-8 in. / 100-200 mm industrial drain, pipe, and sewer cleaning.

- Delivers quality results with the most common equipment setups

- Repairable and rebuildable, field serviceable

- Newly designed centralizer boosts durability

- Perfect for 6-18 in. / 150-450 mm industrial drain, pipe, and sewer cleaning.

- Access ports enable viscous fluid change without disassembly for easy field maintenance

- 6-fin unibody design allows steeper rear jets for max pulling/flushing

- Tool profile keeps seals protected and prevents hang-ups

- Perfect for 6-18 in. / 150-450 mm industrial drain, pipe, and sewer cleaning.